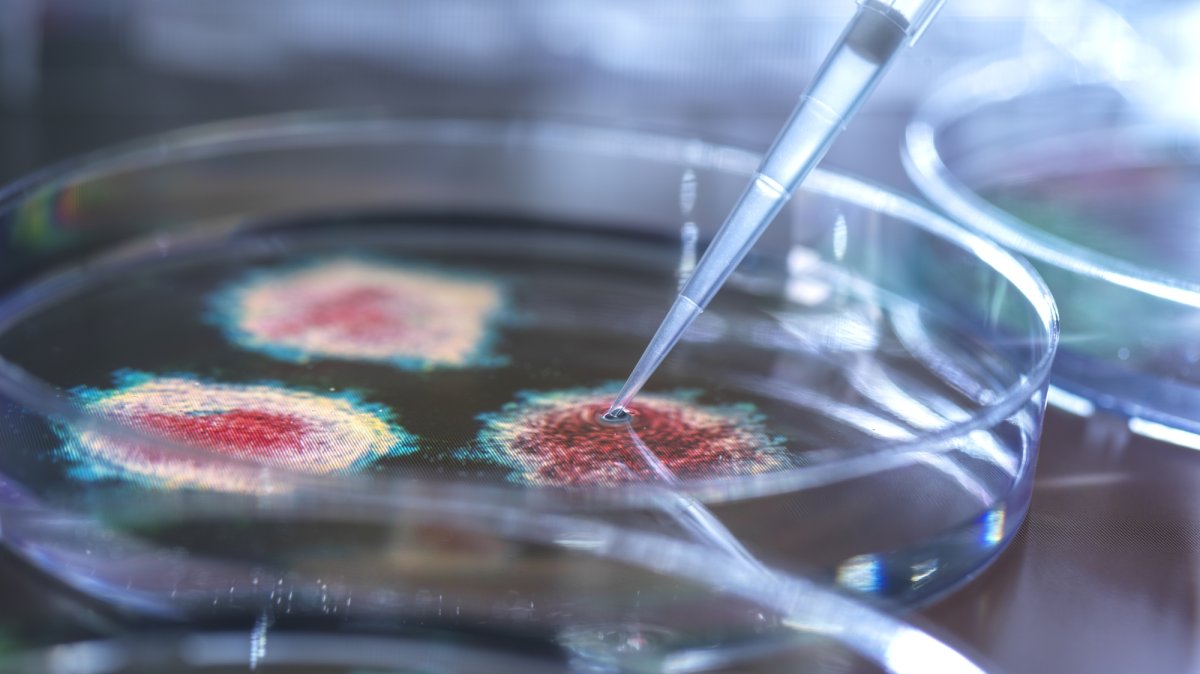

Germany’s chemical trade, Europe’s largest, is starting to see the impression of delayed shipments through the Red Sea, turning into the most recent trade to lift considerations over provide disruptions which have pressured some corporations to cut back manufacturing.

Crucial Asian imports to Europe, starting from automotive components and engineering gear to chemical substances and toys, are at the moment taking longer to reach as container shippers have diverted vessels round Africa and away from the Red Sea and Suez Canal following assaults by Yemen’s Houthis.

Houthi rebels launched assaults on Isreal-bound ships passing by means of the passage in what they known as solidarity with Palestinians in Gaza following relentless assaults of Israel on the besieged strip, which have killed at the very least 25,000 folks up to now, in keeping with the territory’s Health Ministry.

While the German trade has gotten used to provide disruptions within the wake of the pandemic and the Ukraine conflict, the impression of lowered site visitors through the commerce artery is beginning to present, with Tesla’s Berlin manufacturing facility being probably the most distinguished sufferer up to now.

Germany’s chemical substances sector, the nation’s third-biggest trade after automobiles and engineering, with annual gross sales of round 260 billion euros ($282 billion), depends on Asia for round a 3rd of its imports from outdoors Europe.

“My procurement department is currently working three times as hard to get something,” stated Martina Nighswonger, CEO and proprietor of Gechem GmbH & Co KG, which mixes and bottles chemical substances for giant industrial shoppers.

As a results of the delays, Gechem, which makes annual gross sales within the double-digit tens of millions of euros, has lowered manufacturing of dishwasher and bathroom tablets as a result of it might’t get sufficient trisodium citrate in addition to sulfamic and citric acid.

The firm is due to this fact reviewing its three-shift system, Nighswonger stated, including the ripple results from the transport squeeze may stay an issue for at the very least the primary half of 2024.

This is inflicting frank discussions with clients, Nighswonger added.

“If we get three truckloads instead of six, each customer only gets part of their order quantity, but at least everybody gets something,” she stated.

Bigger specialty chemical substances maker Evonik additionally stated it was being hit by “short notice routing changes and delays,” including some ships had modified course as many as 3 times inside a number of days.

The firm stated it was attempting to mitigate the impression by ordering earlier and switching to air freight, which is taken into account a stopgap as a result of some chemical substances can’t be transported by aircraft.

Asian dependence

JPMorgan on Monday stated that whereas delivery disruption within the Red Sea and the Panama Canal was driving chemical costs it may additionally speed up corporations’ restocking efforts and due to this fact result in increased demand.

This, “if sustained, might alleviate the pressure from Chinese chemical exports and potentially result in some strengthening in prices/margin and as a result inventory restocking”, the brokerage wrote.

German trade physique VCI has lengthy pointed to the dependence on Asian imports, saying that whereas manufacturing outages needs to be restricted to particular person circumstances, import delays through the Red Sea have been an extra burden for an already weakened trade.

“The effects are particularly noticeable in medium-sized fine and specialty chemicals companies,” VCI chief economist Henrik Meincke stated, including these corporations typically supply a sizeable proportion of their uncooked supplies from Asia.

The Red Sea transport disaster comes as Germany’s economic system is already beneath stress because of a recession, in addition to excessive labor and vitality prices. According to S&P Global, Europe’s chemical substances sector, together with automobiles and retail, is seen as probably the most weak.

In addition to delayed imports, chemical substances teams level to increased gas prices, as tankers transporting essential uncooked supplies take round 14 days longer to reach, including these prices can solely be partially handed on to clients.

Others are much less impacted.

Covestro, which makes foam chemical substances utilized in mattresses, automotive seats and constructing insulation, expects to incur increased freight costs however added these have been insignificant inside its total spending.

It stated an inside process drive was coping with the difficulty, nonetheless pointing to its robust regional footprint.

Fragrance maker Symrise, too, stated it didn’t count on delays in its deliveries as a result of it had sufficient security shares, and it known as on clients to stay with their regular ordering patterns to move off any unwarranted hoarding.

Wacker Chemie, which provides polysilicon for roughly half the world’s chips, additionally pointed to increased costs however added its business had not been considerably affected up to now.

VCI’s Meincke sees a reasonably low likelihood of widespread manufacturing outages even when the Red Sea state of affairs stays tense, including that with weak demand, crimson tape, and excessive vitality and uncooked supplies prices, the sector already had sufficient to fret about.

Source: www.dailysabah.com